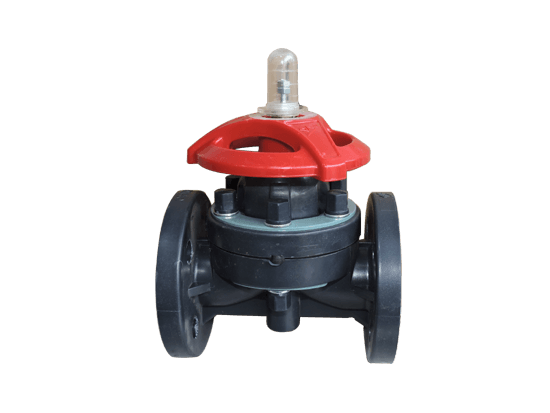

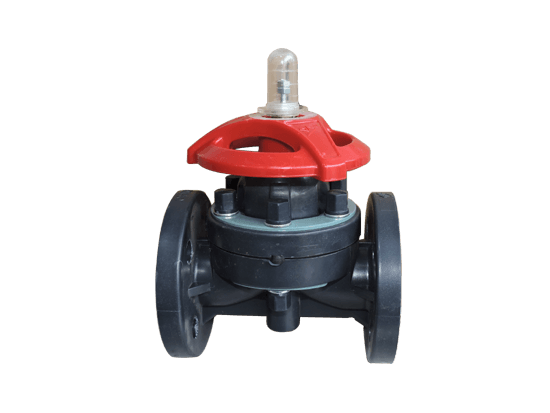

FREE-VALVE manual plastic flange end diaphragm valve is a special form of on-off valve, disc is a diaphragm made of corrosion-resistant soft material,the inner cavity of the bonnet and the driving parts are separated,the valves isolate the bonnet and working parts from the line fluid, so that the stem and other parts above the diaphragm are not subject to media corrosion,so plastic diaphragm valve eliminate the packing seal structure, and will not produce media leakage,and the vales are widely used in various fields.

1.The diaphragm of using FEP/FPA/PTFE and rubber composite, suitable for variety of corrosive media.Plastic diaphragm valves offer many combinations of body and elastomeric diaphragm materials and are abrasion resistant.

2.The molded flanged body eliminates potentially leaky joints,100% gas seal can be achieved to ensure no leakage in outlet port.

3.No direct contact between metal parts and medium slurry.

4.Bi-directional and full flowing path can reduce pressure drop, weaken abrasion and prolong the service working life.

5.Smoother than metal for better flow rates.

6.Working temperature: FRPP -14ºC~ +90ºC,UPVC -10ºC~ +60ºC,PVDF -40ºC~ +150ºC,CPVC -20ºC~ +95ºC

FREE-VALVE manual plastic flange end diaphragm valve body are made of plastic material, which makes it highly resistant to acids, bases, salts, and other chemicals. This means that plastic diaphragm valve will last longer than traditional metal valves to corrosion and chemical erosion. The valves are widely used in chemical industry, medicine and other industrial sectors to achieve the cutting of acid, alkali and other corrosive media in the production process.

If you have any question or comment, please contact us without hesitation. We will reply you as soon as possible.( * is required information)

.png)

.png)