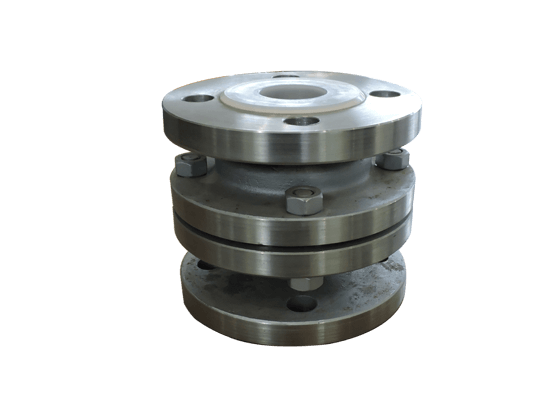

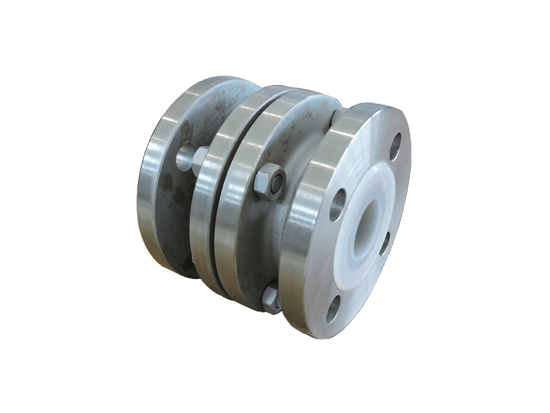

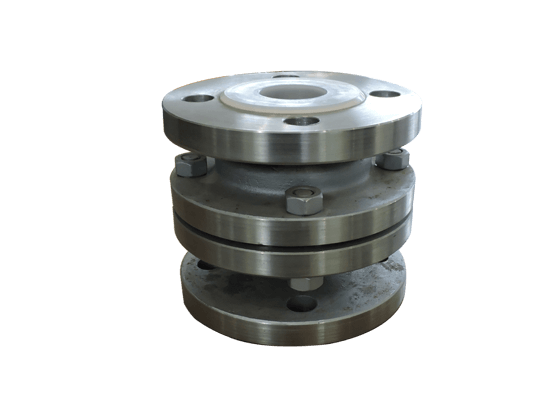

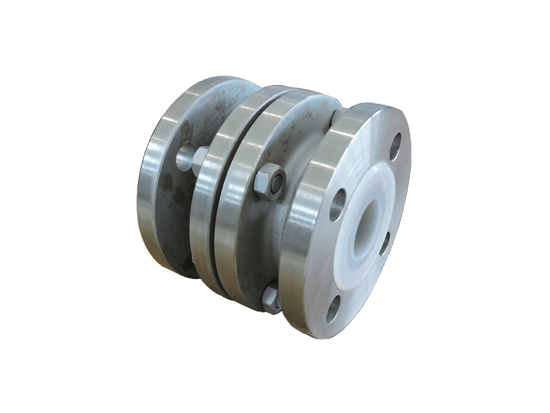

FREE-VALVE fluorine lined lift check valve relies on the disc to do the lifting movement along the axis of the valve body to realize that the valve can automatically prevent fluid backflow. The valve disc opens under the action of fluid pressure, and the fluid flows from the inlet port to the outlet port. When the pressure on the inlet port is lower than that on the outlet port, the valve disc automatically closes under the action of factors such as fluid pressure difference and gravity to prevent fluid backflow. The valve is usually installed in a vertical line.

1.The valve disc and valve stem are designed as one piece part, which can prevent the possibility of the inner parts being flushed out of the valve body caused by the pressure fluctuation of the pipeline.

2.Easy to install,the valve can be used for vertical installation.

3.Fluorine lined check valve adopts special molding process to line the inner wall of the body shell with fluorine plastic, which can resist the corrosion of strong acid and alkali.

4.The valve is straight flow structure, and the valve disc is lifted along the valve body path axis.

5.The lining material is optional, which can be applied to a variety of media ,the valve has good corrosion resistance.

FREE-VALVE fluorine lined lift check valve are automatic valves that permit medium to flow in only one direction ,preventing process flow from reversing.The valve has excellent anti-corrosive performance and is suitable for a variety of strong corrosion conditions, and is widely used in petroleum, chemical, dyeing, pesticide, acid and alkali making industries, etc.

If you have any question or comment, please contact us without hesitation. We will reply you as soon as possible.( * is required information)