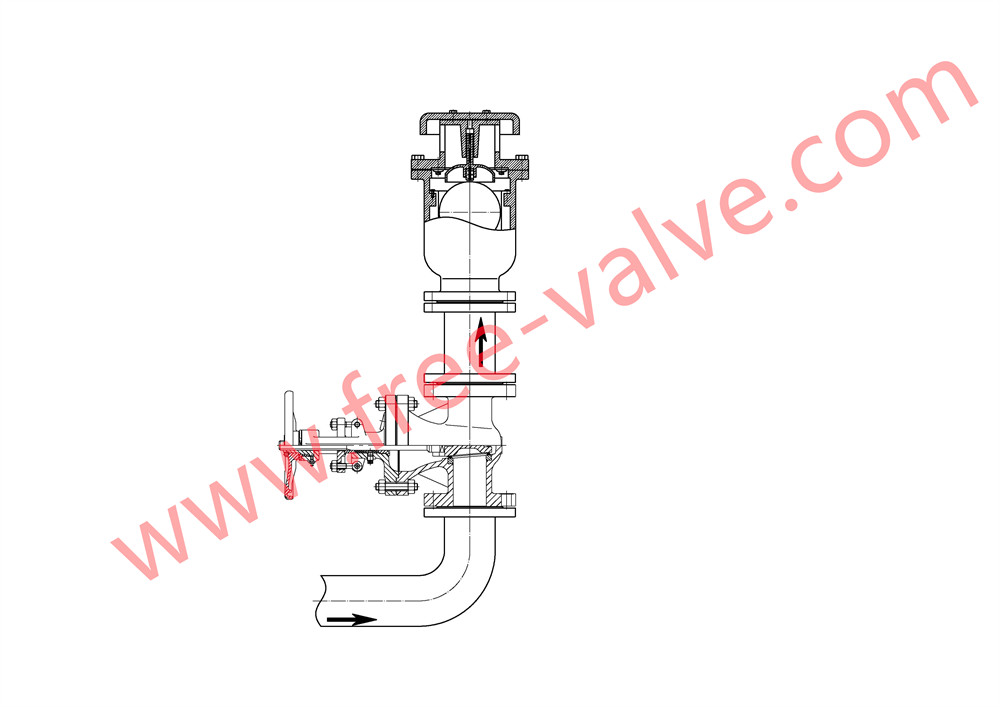

stainless steel Flanged end Single vent Automatic Quick Air Release Valve DN200

FREE-VALVE stainless steel Flanged end Single vent Automatic Quick Air Release Valve is a barrel shaped valve body, which consists of stainless steel floating balls,Stainless steel filter basket and plug heads.

FREE-VALVE stainless steel Flanged end Single vent Automatic Quick Air Release Valve is a barrel shaped valve body, which consists of stainless steel floating balls,Stainless steel filter basket and plug heads.Composite exhaust valve is installed at the outlet of Pump or in the water supply and distribution pipeline to remove a large amount of accumulated air from the pipeline, so as to improve the efficiency of the water pipe and pumping unit. In case of negative pressure in the pipeline, the valve can quickly suck in air to protect the pipeline from damage caused by negative pressure.

Features

1.The valve is a barrel shaped valve body,the valve body is manufactured in integrated structure.

2.The valve is mainly composed of stainless steel valve ball, stainless steel filter basket and plug heads.

3.The valve is mainly installed at the highest point of the pipeline or at the place where the air is enclosed.

4.The medium working pressure should not be less than 0.02Mpa during the valve using.

Technical Specification:

Size Range: DN50~DN300

Temperature of Media:Low Temperature

Body material:Ductile Iron,WCB,Stainless steel

Floating ball:SS316/SS304

Sealing ring:NBR/fluorine rubber

Applicable Temperature: 0~150℃

Connection Type: Flange

Pressure test:GB/T13927, API598

Application:

FREE-VALVE stainless steel Flanged end Single vent Automatic Quick Air Release Valve is used at the highest point of the pipeline or at the place where the air is closed. It expels the gas in the pipeline to dredge the pipeline and achieves normal work.If the exhaust valve is not installed, the liquid flowing in the pipeline generates dynamic heat which causes the gas to form a short circuit and makes the outlet capacity of the pipeline fall short of the requirement. Secondly, power cut and shutdown occur when the pipeline is running. Pump pipe will appear negative pressure, and will cause pipe vibration or rupture, exhaust (suction) valve on the rapid suction of air into the pipe, to prevent pipe vibration or rupture.