Pneumatic Flanged Three-Way Changeover Ceramic Lined Gate Valve

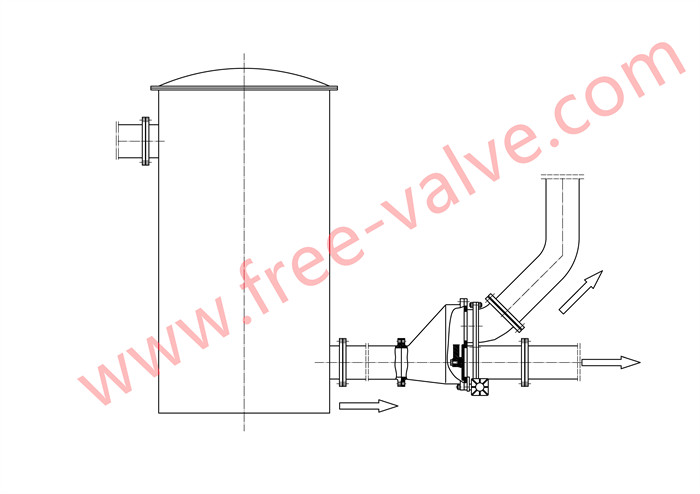

FREE-VALVE brand Pneumatic Ceramic Lined Three-Way Changeover Gate Valve is a commutator separating the materials conveyed in one way into two ways. The valve is designed with one inlet port and two outlet ports, of which one outlet port is set forward along the direction of the main pipe, and the other outlet port is set below the main pipe or horizontal direction, and there is an angle with the main pipe

FREE-VALVE brand Pneumatic Ceramic Lined Three-Way Changeover Gate Valve is a commutator separating the materials conveyed in one way into two ways. The valve is designed with one inlet port and two outlet ports, of which one outlet port is set forward along the direction of the main pipe, and the other outlet port is set below the main pipe or horizontal direction, and there is an angle with the main pipe.This valve is extensively applied in conveying system of thermal power plant for conveyance of dry, loose solid materials such as dry ash, raw cement, limestone, pulverized coal and other powder materials. It provides a reliable commutator for positive-pressure air conveyance in pipelines.

Features

- The valve design has oneinlet port and two outlet ports, one of outlet ports can be customized according to customer requirements (usually 45 degrees);

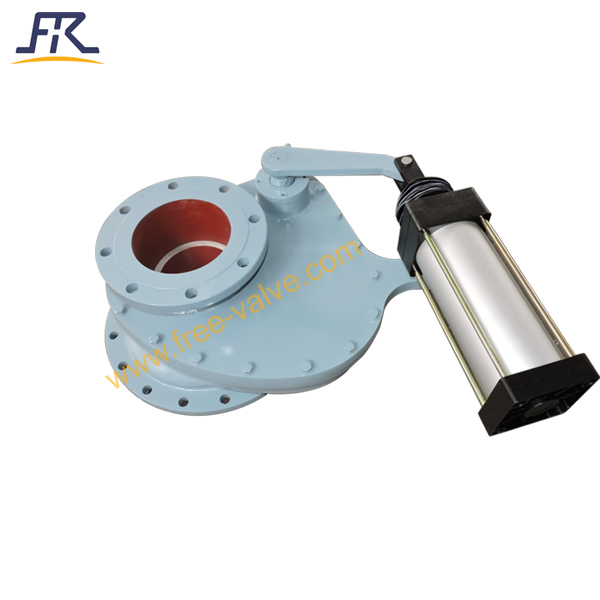

- The pneumatic actuator drives the valve disc to move back and forth between the two discharge ports through the rotating shaft and the swinging arm to complete the switching and conveying of materials.

- The cylinder piston rod does not contact with the medium directly, which greatly prolongs the service life of the cylinder and has a higher service temperature without damaging the cylinder.

- The sealing faces of the valve are made of toughened engineering ceramics with good abrasion resistance and prolonged service life.

- Product with customized structural length and connection size is available.

- The valve disc rotational motion can avoid the ash deposition on the sealing surface during opening and closing, so the valves have much longer service.

- The spring between the disc and disc seat is loaded with a floating connection. The spring force of the disc always matches the valve seat, ensures the sealing of the valve, and also helps to compensate for expanding when heated and contracting when cooled ,and sealing surface wear.

- The angled elbow can also be designed as ceramic wear-resistant elbow or lined with wear-resistant alloy material according to the user’s requirements.

Technical Specification:

| 1 | Size Range | NPS4~NPS12,DN100~DN300 |

| 2 | Nominal pressure | Class 150 /PN10/PN16 |

| 3 | Applicable Temperature | 0~200℃ |

| 4 | Connection Type | Flange |

| 5 | Disc | Carbon steel+ceramic,stainless steel+ceramic |

| 6 | Seat | Ceramic/Tungsten |

| 7 | Pressure test | GB/T13927, API598 |

| 8 | Face to Face | GB/T12221, ASME B16.10 |

| 9 | Operating Type | Pneumatic |

| 10 | Model | FRZ645TC/FRZ645Y |

Main outline and connection dimensions

| DN | PN | L | D | D1 | D2 | n-∅d |

| DN125 | PN10 | 250 | 210 | 186 | 8-∅18 | |

| DN150 | PN10 | 285 | 240 | 210 | 8-∅22 | |

| DN200 | PN10 | 340 | 295 | 266 | 8-∅22 | |

| DN250 | PN10 | 395 | 350 | 320 | 12-∅22 | |

| DN300 | PN10 | 440 | 400 | 370 | 12-∅22 |

Note:Face to Face dimension “L” can be customized according to customer requirements

Application:

FREE-VALVE sealing element in changeover valve is made of wear-resistant ceramic material and combined after match grinding,the hardness can reach 60~70HRC, which solves the problem that the sealing surface is easy to be eroded due to material erosion and the service life is not high,so it brings good use effect and economic benefit for end users.The Pneumatic Ceramic Lined Three-Way Gate Valve are widely used in fly ash, slag, cement raw material, limestone, pulverized coal, bentonite, talc, barite and other powder granular solid dry loose material conveying system.