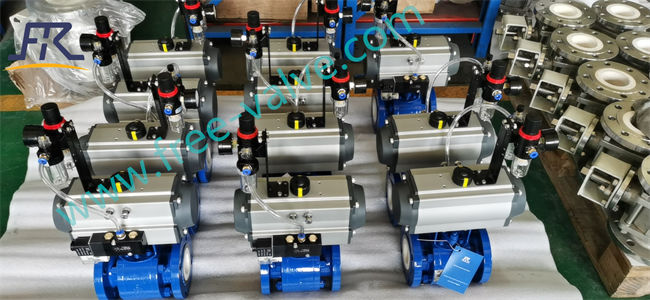

Pneumatic Conveying Lithium Powder Ceramic Ball Valve

FREE-VALVE’s Pneumatic Conveying Lithium Powder Ceramic Ball Valves are designed with engineering ceramics the engineering ceramics internal parts provide excellent wear resistance, the ceramic ball valves are widely used as an open and close function as well as a throttling control tasks in corrosive medium with abrasive solids medium .

FREE-VALVE’s Pneumatic Conveying Lithium Powder Ceramic Ball Valves are designed with engineering ceramics the engineering ceramics internal parts provide excellent wear resistance, the ceramic ball valves are widely used as an open and close function as well as a throttling control tasks in corrosive medium with abrasive solids medium .

Features:

1.The hardness of the ceramic material can be higher than HRC80.

2.Engineering internal parts of ceramic ball valve provide superior protection from corrosive and abrasive medium.

3.The valve has a floating ball design, the ball is floating, the ball has a defined clearance and is pressed against the downstream seat under the differential pressure to achieve sealing.

4.Pneumatic operated fully make use of the compress air resource on site .

5. You could achieve closed production by closed pipe transportation ,make a green production and protect the environment .

6.As dust is reduced, you could increased production capacity greatly .

Technical Specification

Flange Standards ASME B16.5,GB/T9113

Nominal Pressure 1.0MPa,Class150

Size Range :DN50~DN 200, NPS2 ~NPS8

Connection type: Flange

Working Temperature ≤200℃

Operating Type: Manual, Pneumatic and Electric

Sealing surface material:Engineering ceramic

Ball material:Zirconia ceramic

Pressure test GB/T13927, API598

Face to Face GB/T12221, ASME B16.10

Application

You will find FREE-VALVE’s Ceramic ball valves for pneumatic conveying Lithium powder are installed at Lithium battery industry (battery anode material)