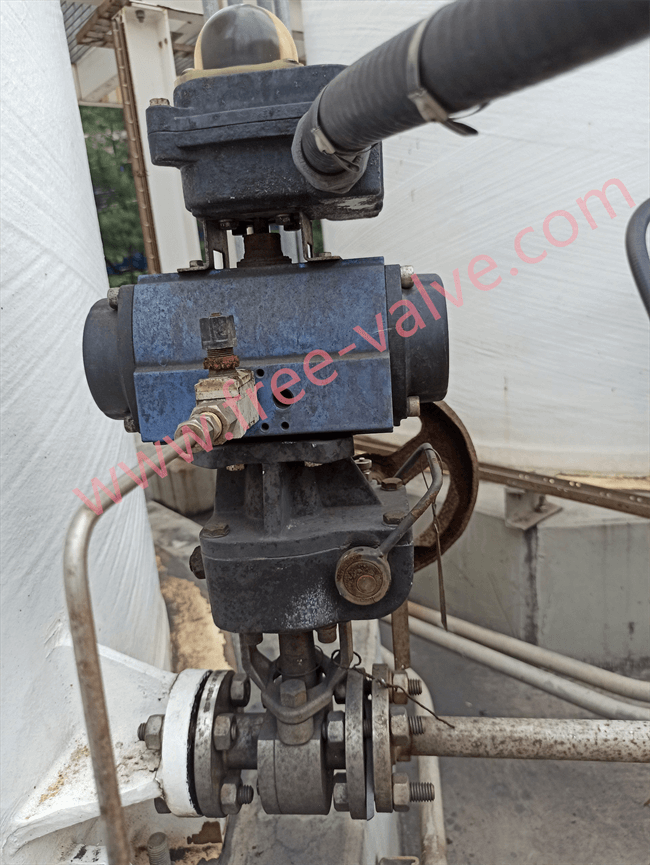

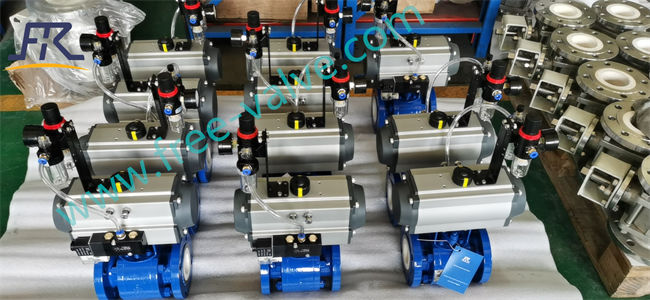

Pneumatic Ceramic Lined Segment Ball Valve with V Port Ball for Chemical Industry

FREE-VALVE Pneumatic Operated Ceramic Lined Ball Valves are that V-port ceramic ball provides precise throttling control in the valve’s opening and closing, with more accurate and flexible adjusting performance.Besides,the self-lubricating capability of engineering ceramic ensures the good sealing after polishing,during the opening and closing process

FREE-VALVE Pneumatic Ceramic Lined Segment Ball Valves are that V-port ceramic ball provides precise throttling control in the valve’s opening and closing, with more accurate and flexible adjusting performance.Besides,the self-lubricating capability of engineering ceramic ensures the good sealing after polishing,during the opening and closing process,the V shaped channel of the ball and ceramic seat have a wedge-shaped shearing effect,which can cut off fibers and particles in media during the opening and closing process to prevent the ball core from sticking.

Features:

- The hardness of the ceramic material can be higher than HRC80.

- Approximate equal percentageflow regulation characteristics and works at small opening.

- The flow adjusting more accurately and flexibly,with large adjustable range,fast adjustment speed,simple maintenance.

- Straight-through design, no flow blocking element in the valve cavity.

- ZrO2 ceramic ball have good self-cleaning property.

Technical Specification

Size Range :DN25~DN 200, NPS1 ~NPS8

Nominal Pressure:1.0MPa,Class150

Flange Standards:ASME B16.5,GB/T9113

Connection type:Flange

Working Temperature ≤200℃

Operating Type: Pneumatic and Electric

Seat material:Engineering ceramic

Ball material:Zirconia ceramic

Pressure test:GB/T13927, API598

Face to Face:GB/T12221, ASME B16.10

Model:FRQV641TC

Main outline and connection dimensions

| DN | d | PN | L1 | L2 | D | D1 | D2 | n-M/n-∅Z | |

| DN25 | 20 |

PN10

|

127 | 140 | 115 | 85 | 68 | 4-M12/4-∅14 | |

| DN32 | 25 | 140 | 165 | 140 | 100 | 78 | 4-M16/4-∅18 | ||

| DN40 | 32 | 165 | 165 | 150 | 110 | 88 | 4-M16/4-∅18 | ||

| DN50 | 40 | 178 | 203 | 160 | 125 | 99 | 4-M16/4-∅18 | ||

| DN65 | 50 | 190 | 222 | 180 | 145 | 118 | 4-M16/4-∅18 | ||

| DN80 | 65 | 203 | 241 | 200 | 160 | 132 | 8-M16/8-∅18 | ||

| DN100 | 80 | 229 | 305 | 220 | 180 | 156 | 8-M16/8-∅18 | ||

| DN125 | 100 | 356 | 250 | 210 | 186 | 8-M16/8-∅18 | |||

| DN150 | 125 | 394 | 285 | 240 | 210 | 8-M20/8-∅22 | |||

| DN200 | 150 | 457 | 340 | 295 | 266 | 8-M20/8-∅22 | |||

Flow coefficient table

| Nominal size | Cv Value | Torque(△p=1.0MPa) | ||||

| O port | V30° | V45° | V60° | N.M | ||

| DN25 | 1” | 18.2 | 5 | 8 | 12 | 15 |

| DN32 | 1-1/4” | 28.5 | 8 | 12 | 18 | 26 |

| DN40 | 1-1/2” | 47 | 13 | 20 | 30 | 35 |

| DN50 | 2” | 73 | 21 | 31 | 46 | 42 |

| DN65 | 2-1/2” | 114 | 32 | 48 | 72 | 64 |

| DN80 | 3” | 181 | 51 | 76 | 115 | 90 |

| DN100 | 4” | 292 | 82 | 123 | 185 | 130 |

| DN125 | 5” | 456 | 128 | 192 | 289 | 220 |

| DN150 | 6” | 712 | 201 | 300 | 452 | 250 |

| DN200 | 8” | 1025 | 289 | 432 | 650 | 490 |

Application

FREE-VALVE Pneumatic Operated Ceramic Lined Ball Valves can serve dual purpose,functioning both as an On/Off Valve and as a precise equal percentage throttling control valve,the valves are suitable for water,steam,oil,lime slurry,liquid chlorine,nitric acid,acetic acid,oxidizing substances,urea and other medium.