Fully PTFE FEP lined weir type diaphragm valve

FREE-VALVE Fully PTFE FEP lined weir type diaphragm valve is a special form of on-off valve, disc is a diaphragm made of corrosion-resistant soft material,the diaphragm separates the bottom body cavity from the top bonnet cavity

FREE-VALVE Fully PTFE FEP lined weir type diaphragm valve is a special form of on-off valve, disc is a diaphragm made of corrosion-resistant soft material,the diaphragm separates the bottom body cavity from the top bonnet cavity,so that the stem, metal disc and other parts above the diaphragm are not subject to media corrosion,so fluorine lined diaphragm valve eliminate the packing seal structure, and will not produce media leakage.

Features:

- The diaphragmof using FEP/FPA/PTFE and rubber composite, suitable for variety of corrosive media.

- 100% gas seal can be achieved to ensure no leakage in outlet port.

- No direct contact between metal parts and medium

- Bi-directional and full flowing path can reduce pressure drop, weaken abrasion and prolong the serviceworking

Technical Specification

1) Size Range: DN25~DN400

2) Pressure Range: Class 150 /PN10 /PN16

3) Connection Type: Flange

4) Lining Material:PTFE , PFA , FEP

5) Body material:WCB, CF8 ,CF8M

6) Pressure test:GB/T13927, API598

7) Face to Face: GB/T12221, ASME B16.10

8) Operating Type: Manual Handwheel

Temperature of use and suitable media of body lining material

| Lining material | Service temperature,°C | Application medium |

| NR | -10°C~+85°C | exclusive of strong oxidants:hydrochloric acid, fluorosilicic acid, phenolic acid, hydrochloric acid, 30 percent sulfuric acid, 50 percent hydrofluoric acid, 80 percent phosphoric acid, alkali, salt, gold plating solution, sodium hydroxide, potassium hydroxide, neutral salt aqueous solution, 10 percent sodium hypochlorite, ammonia, most alcohols, organic acids and aldehydes,ect |

| EPDM | ≤120°C | It has the similar acid and alkaline properties of natural glue, and it is very good for low pressure steam, hot water and cold water. |

| PTFE(F4) | ≤180°C | Strong acid, strong base, strong oxidant, organic solvent, etc |

| FEP(F46) | ≤120°C | Any organic solvents or reagents, xi or concentrated inorganic acids, bases, ketones, aromatics, chlorinated hydrocarbons, etc |

| PFA | ≤180°C | Strong acid,strong alkali,Strong oxidant, organic solvent, etc |

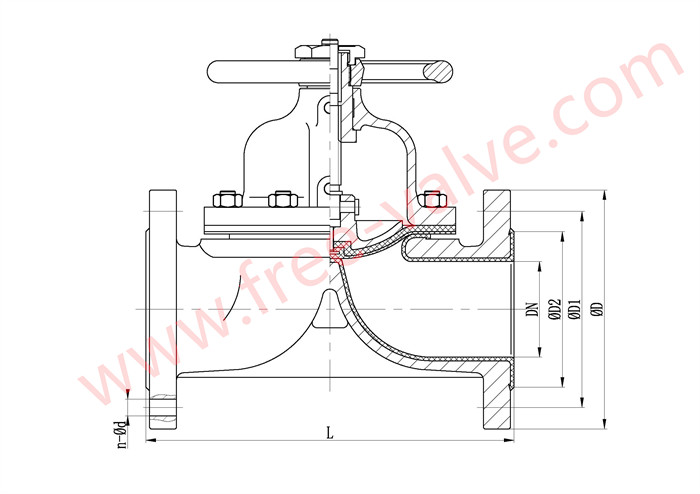

Main outline and connection dimensions

| DN | DN | PN | L | D | D1 | n-∅d |

| EG41W/J/F46 | DN20 | PN10 | 121 | 105 | 75 | 4-∅14 |

| DN25 | 131 | 115 | 85 | 4-∅14 | ||

| DN32 | 150 | 140 | 100 | 4-∅18 | ||

| DN40 | 163 | 150 | 110 | 4-∅18 | ||

| DN50 | 194 | 165 | 125 | 4-∅18 | ||

| DN65 | 220 | 185 | 145 | 4-∅18 | ||

| DN80 | 258 | 200 | 160 | 8-∅18 | ||

| DN100 | 309 | 220 | 180 | 8-∅18 | ||

| DN125 | 362 | 250 | 210 | 8-∅18 | ||

| DN150 | 412 | 285 | 240 | 8-∅22 | ||

| DN200 | 529 | 340 | 295 | 8-∅22 | ||

| DN250 | 641 | 395 | 350 | 12-∅22 | ||

| DN300 | 757 | 445 | 400 | 12-∅22 | ||

| G41FW/J/F46 | DN15 |

PN10 |

125 | 95 | 65 | 4-∅14 |

| DN20 | 135 | 105 | 75 | 4-∅14 | ||

| DN25 | 145 | 115 | 85 | 4-∅14 | ||

| DN32 | 160 | 140 | 100 | 4-∅18 | ||

| DN40 | 180 | 150 | 110 | 4-∅18 | ||

| DN50 | 210 | 165 | 125 | 4-∅18 | ||

| DN65 | 250 | 185 | 145 | 4-∅18 | ||

| DN80 | 300 | 200 | 160 | 8-∅18 | ||

| DN100 | 350 | 220 | 180 | 8-∅18 | ||

| DN125 | 400 | 250 | 210 | 8-∅18 | ||

| DN150 | 460 | 285 | 240 | 8-∅22 | ||

| DN200 | 570 | 340 | 295 | 8-∅22 | ||

| DN250 | 680 | 395 | 350 | 12-∅22 | ||

| DN300 | 790 | 445 | 400 | 12-∅22 | ||

| DN350 | 900 | 505 | 460 | 16-∅22 | ||

| DN400 | 1000 | 570 | 515 | 16-∅26 |

Note:in the suitable media column, “W” means the body without lined,“J” means the body lined hard rubber,“F46” means the body lined fluorine plastic,

Application

FREE-VALVE Fully PTFE FEP lined weir type diaphragm valve are widely used in chemical industry, medicine and other industrial sectors to achieve the cutting of acid, alkali and other corrosive media in the production process.