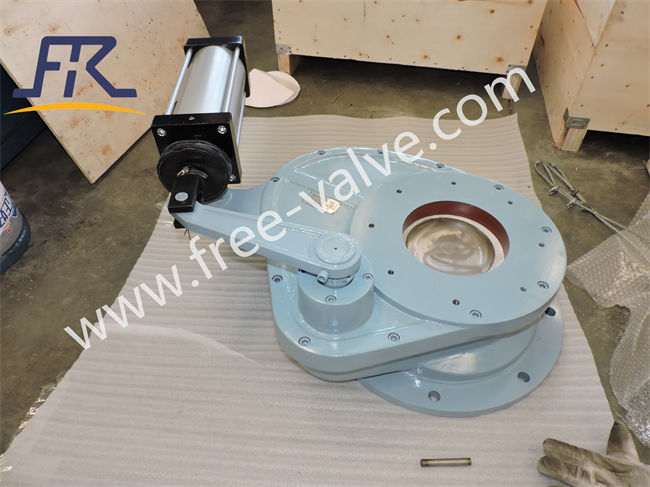

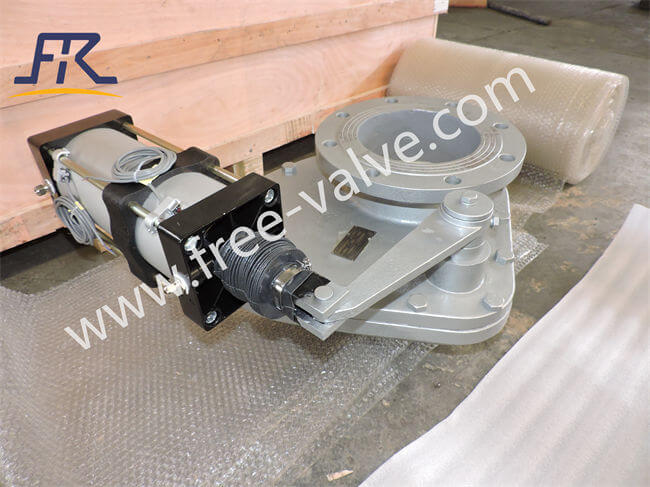

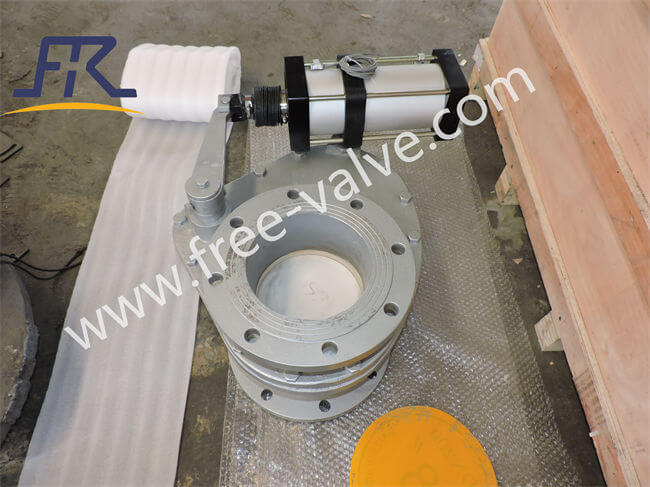

FREE–VALVE’s FRXZ644TC Pneumatic Anti wear Ceramic Lined Rotary Double Disc Discharge Ash Gate Valves are designed for pressurized and vacuum systems including dense and dilute phase pneumatic conveying systems, discharge and vent applications in steel plant and coal power. The double ceramic sealing faces of the valves are well ground and polished, which is ensure a reliable sealing performance of the valve,the valve is used to replace the dome valve in the pipe line of the ash system.

Features

1. The cylinder piston rod does not contact with the medium directly, which greatly prolongs the service life of the cylinder and has a higher service temperature without damaging the cylinder.

2. The sealing faces of the valve are made toughened engineering ceramics with good abrasion resistance and prolonged service life.

3. Product with customized structural length and connection size is available.

4. The valve disc rotational motion can avoid the ash deposition on the sealing surface during opening and closing, so the valves have much longer service.

5. The spring between the disc and disc seat is loaded with a floating connection. The spring force of the disc always matches the valve seat, ensures the sealing of the valve, and also helps to compensate for expanding when heated and contracting when cooled ,and sealing surface wear.

6. The blow sweep port or automatic blow sweep device can be set on the valve body according to different operating conditions.

Technical Specification:

1) Size Range: NPS4~NPS12,DN100~DN300

2) Pressure Range: Class 150 /PN6 /PN10

3) Applicable Temperature: 0~200℃

4) Connection Type: Flange or threaded hole

5) Sealing material: engineering ceramics

6) Pressure test:GB/T13927, API598

7) Face to Face: GB/T12221, ASME B16.10

8) Valve body : GB/T12224,ASME B16.34

9)Operating Mode: Pneumatic

Application:

FREE–VALVE’s FRXZ644TC Pneumatic Anti wear Ceramic Lined Rotary Double Disc Discharge Ash Gate Valves are suitable for coal fired power plant, steel plant, cereals transport system, cement transport systems. In these applications, pneumatic conveying method is used to reduce manpower demand, and improve system efficiency and reliability, and is easy to realize automation.