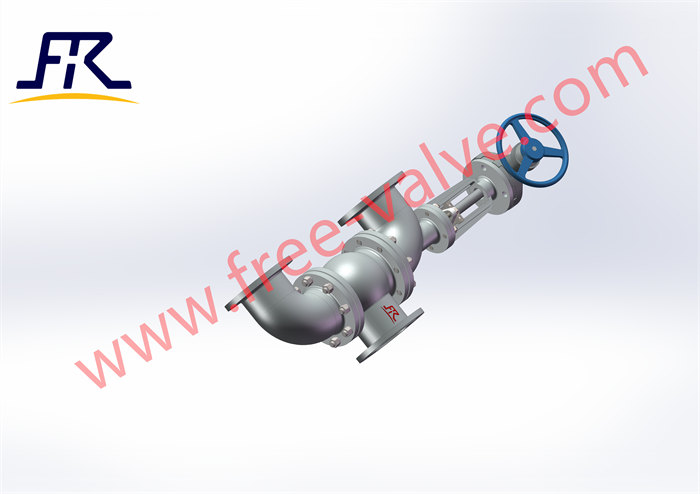

Electric operating triplet commutation Alumina slurry globe valve FRJ943Y

FREE-VALVE triplet commutation Alumina slurry globe valve is an inverted process valve developed according to the alumina process, which adopts the design principle of superimposed multi-function valve, and is designed as a one inlet and two outlets structure. Slurry diversion and conduction is realized by changing valve stem structural and seal of upper and lower valve body .

FREE-VALVE triplet commutation Alumina slurry globe valve is an inverted process valve developed according to the alumina process, which adopts the design principle of superimposed multi-function valve, and is designed as a one inlet and two outlets structure. Slurry diversion and conduction is realized by changing valve stem structural and seal of upper and lower valve body .

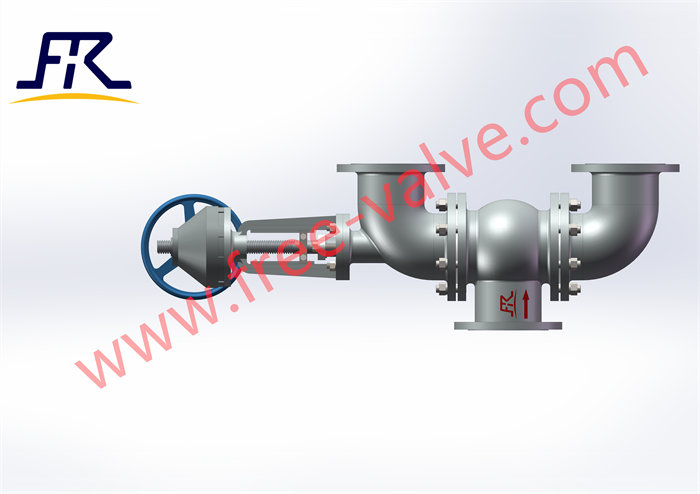

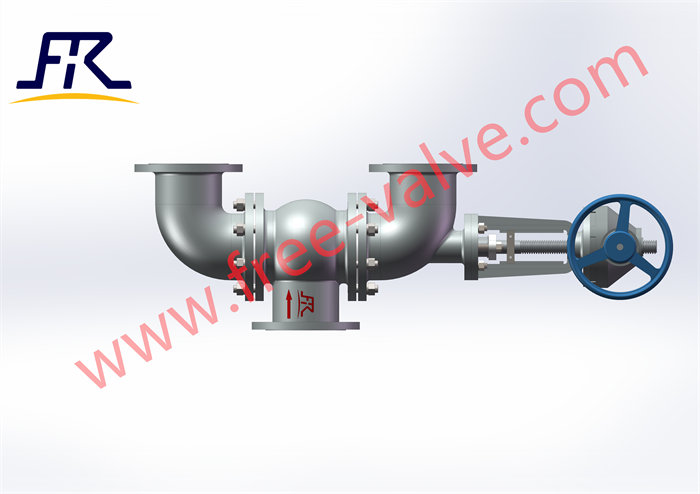

When the valve disc is closed downward, the lower seal of the valve is closed, and the slurry enters the upper outlet through the valve cavity to realize the reverse process; While the disc is lifted upwards, the upper seal of the valve is closed, and the slurry enters the lower outlet through the valve cavity to realize the reverse process. So the speed of the alumina dissolution process is greatly improved, more over a lot of production costs is saved for users.

Features

- The valve is designed as oneinlet and two outlets structure, so the inlet and outlet flow channels have switching functions, and the two flow channels can be opened and closed alternately as needed.

- Short stroke, fast and convenient opening and closing.

- Small flow resistance and less medium pressure loss.

- The sealing surface material adopts WC alloy and other types of cemented carbide, which has high hardness, erosion resistance and long service life.

- The structure of inletand outlet port can be designed as parallel, vertical or inclined.

- The seat can be replaced easily .

- Valve driving modelincludes manual, electric, pneumatic,worm gear , etc.

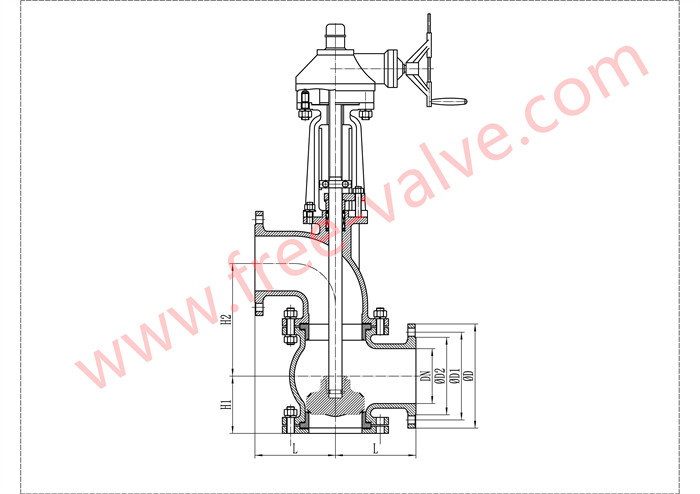

Main outline and connection dimensions

| DN | PN | L | D | D1 | D2 | n-∅d | H1 | H2 |

| 50 | PN16 | 75 | 165 | 125 | 99 | 4-∅18 | 55 | 105 |

| 65 | PN16 | 100 | 185 | 145 | 118 | 4-∅18 | 70 | 135 |

| 80 | PN16 | 120 | 200 | 160 | 132 | 8-∅18 | 85 | 165 |

| 100 | PN16 | 170 | 220 | 180 | 156 | 8-∅18 | 135 | 230 |

| 125 | PN16 | 183 | 250 | 210 | 184 | 8-∅18 | 130 | 256 |

| 150 | PN16 | 220 | 285 | 240 | 211 | 8-∅22 | 157 | 308 |

| 200 | PN16 | 248 | 340 | 295 | 266 | 12-∅22 | 200 | 268 |

| 250 | PN16 | 300 | 405 | 355 | 319 | 12-∅26 | 230 | 400 |

| 300 | PN16 | 330 | 460 | 410 | 370 | 12-∅26 | 260 | 460 |

| 350 | PN16 | 370 | 520 | 470 | 429 | 16-∅26 | 355 | 680 |

| 400 | PN16 | 425 | 580 | 525 | 480 | 16-∅30 | 410 | 780 |

| 450 | PN16 | 475 | 640 | 585 | 548 | 20-∅30 | 460 | 870 |

| 500 | PN16 | 530 | 715 | 650 | 609 | 20-∅33 | 510 | 980 |

| 600 | PN16 | 635 | 840 | 770 | 720 | 20-∅36 | 610 | 1160 |

Note: Our company also produces other pressure grade products, flange connection size according to customer requirements according to GB/T9113 or ASME B16.5.

Technical Specification:

Flange connection:ASME B16.5,GB/T9113

Design standard:ASME B16.34,GB/T12224

Pressure Range:Class150~Class600

Size Range:DN50~DN 500, NPS2~NPS20

Material:Carbon steel, stainless steel

Connection type:Flange

Working Temperature:≤425℃

Operating Type:Pneumatic, manual, electric

Sealing surface material:Alloy ,Ceramic

Pressure test:GB/T13927, API598

Application

FREE-VALVE triplet commutation Alumina slurry globe valve is installed in front or behind of the tank of alumina production .As the valve is an integral assembly valve, it realizes the dual or multi-purpose of one valve, which greatly optimize the past aluminum oxide plant reverse process installation structure, and also facilitates the mutual cooperation and conversion process of the inverted process system. The valve is widely used in alumina, metallurgy and other industries with slurry medium .