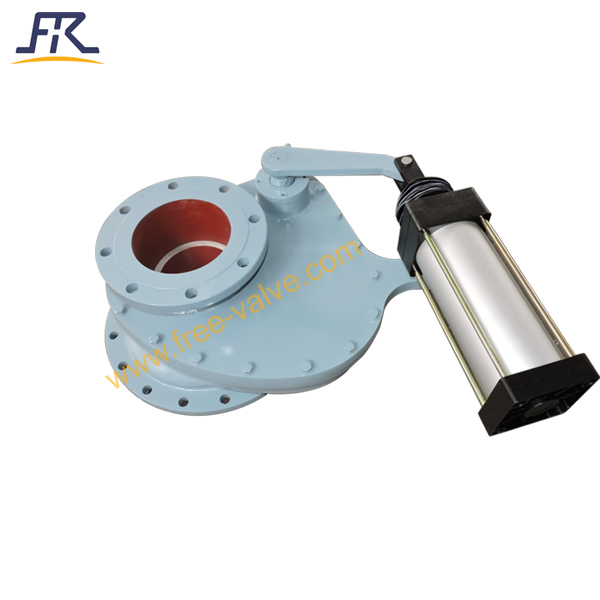

Double acting pneumatic knife gate valve

Double acting pneumatic knife gate valves are suit for any abrasive medium and operated by double acting pneumatic .

Double acting pneumatic knife gate valves are composed of double acting pneumatic actuator and knife gate valve. They are used on industrial pipeline for on-off operation. The structure of body and seat eliminates clogging shutoff for flow with fine particles.The disc bottom of knife gate valve is made into a blade shape with the purpose to cut some soft materials such as fiber,pulp or wood pulp, and it also serves favorable closing and opening.

Features:

- knife gate valve is composed of narrow body and sliding gate.

- The gate has sharp blade that can separated or cut the solid particles in the fluid media.

- The polishing treatment on the gate surface strengthens its penetrating power and effectively guarantees the service life of both packing and valve seat.

- The bottom of valve body is provided with the gate hold down device that can safely pressure the gate tightly on the valve seat in order to ensure valid tight-seal.

- Double acting type pneumatic actuator can save the labor cost largely .

Technical Specification:

1)Size Range: DN50~DN600

2)Pressure Range: PN10

3) Applicable Temperature: 0~200℃

4) Connection Type: Wafer

5) Sealing material: Rubber,PTFE,Metal seal

6) Body Material: Carbon steel,stainless steel

7) Disc material:Stainless steel

8) Pressure test:GB/T13927, API598

9) Face to Face: GB/T12221, API609

10) Valve body : GB/T12224,ASME B16.34

11)Operating Mode: Double acting type pneumatic actuator

Application:

- Mining, coal washing, iron and steel industry used for washing coal pipes, filter slurry pipes, discharging ash pipes, etc.

- Purification systemused for wastewater, mud, sewage and water with suspended solids.

- Paper industryused for any mixture of pulp, material and water of any concentration.

- Power station ash removal used for slag slurry, unloading CaCo3 powder from silo bottom hopper.