Pneumatic conveying is powered by compressed air , conveying powdery materials from one end to the other end in a closed container. Pneumatic conveying is used in a wide range of industries, such as pulverized coal, fly ash and furnace slag in coal power plants, chemical raw materials in the chemical industry, cement and lime in the construction industry, various powder or granular materials in food, medicine and health industries.

Reasonable valve structure design is very important in pneumatic conveying system . Pneumatic rotary ceramic lined gate valves work as feed valve in the warehouse were installed above pump, because the system process require feed valve should be opened every 10 minutes. Coal ash is quite abrasive and makes the valve wear more serious, this led to the installation and maintenance cost is quite high .

When the air come into the stock bin ,coal ash will be bonded into pieces,leading to medium cannot smoothly through the valve.In order to problem of the previous feed valve ,FREE-VALVE company developed pneumatic ceramic lined rotating gate valves compare with the previous dome valve ,life time of the valve have been increased and the maintenance costs have been greatly decreased .

According to the working conditions of ash transporting system medium requirements, pneumatic rotating ceramic lined gate valve are designed with ceramic sealing pair, ceramic lined seat and valve body are assembled by bonding or thermal expansion technology.

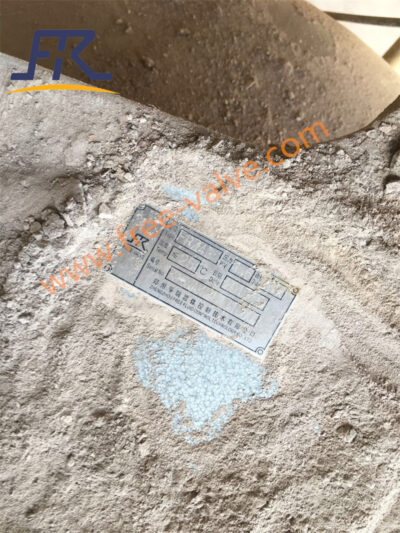

The photos show that FREE VALVE brand pneumatic ceramic lined rotating gate valves were installed someone coal power plant at Vietnam.