FREE-VALVE’s abrasive &corrosive resistant ceramic ball valves are designed with engineering ceramics the engineering ceramics internal parts provide excellent wear resistance, the ceramic ball valves are widely used as an open and close function as well as a throttling control tasks in corrosive medium with abrasive solids .

Features:

1.The hardness of the ceramic material can be higher than HRC80.

2.Engineering internal parts of ceramic ball valve provide superior protection from corrosive and abrasive medium.

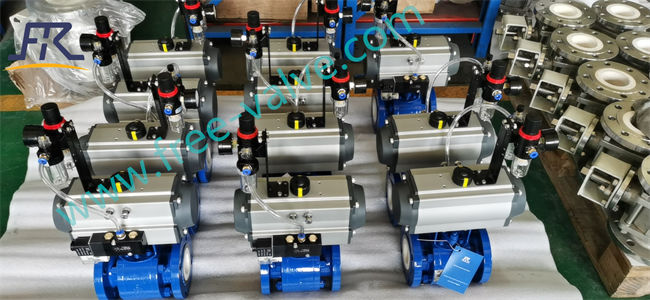

3.Customized actuation types are installed on the ceramic ball valve, the manual lever or gear box, as well as with pneumatic and electric actuators.

4.Customized V type ceramic control valve is also available.

5.The valve has a floating ball design, the ball is floating, the ball has a defined clearance and is pressed against the downstream seat under the differential pressure to achieve sealing.

6.The valve body is in the form of 3-PCS.

Technical Specification

Thread Standards:GB,NPT,BSPT

Nominal Pressure 1.0MPa,Class150

Size Range :DN10~DN 50

Connection type:Flange end

Working Temperature ≤200℃

Operating Type:Manual operation, Pneumatic ,Electric

Sealing surface material:Engineering ceramic

Ball material:Engineer ceramic

Pressure test GB/T13927, API598

Face to Face GB/T12221, ASME B16.10

Application

FREE-VALVE’s anti-abrasive &anti-corrosive ball valves are suitable for Silicon Powder, Alumina Powder, Dry Coal Powder, Limestone Slurry, Gypsum Slurry, Plaster, Fly Ash, Mining Ore, Coal Powder Injection, Metallurgical dust, Thermal Power plant FGD , LiCoO2 powder equipment,Glue industry and food industry.