Application of air release valve in liquid supply pipeline

Feb 10,2025 From: Zhengzhou Free Fluid Control Technology Co.,Ltd

1. General

In long-distance water conveyance projects, due to the influence of topography and other factors, the pipeline is laid at a high rate and a low time. In the long-distance pipeline, the phenomenon of multi-point local gas accumulation will be formed, resulting in water bursting, pressure loss, flow interruption, increased energy consumption, rising operating costs, reducing the service life of the pipeline and other problems, so it is necessary to reasonably use the release valve to eliminate hidden dangers.

2.Problem analysis

The solubility of the air in the pipe in water is related to the ambient temperature and the pressure change in the pipe. when the water pump supplies water, gas will also be brought into the pipeline. When the pipeline is repaired, a large amount of gas will also enter the pipeline with the re-flow of water.

Due to the compressible nature of gases, liquid and gas flows exist in the water supply network. Due to the compressibility of the gas, the gas flow in the pipeline network will form an instantaneous huge pressure, which is several times or even dozens of times the liquid pressure in the pipeline network, thus causing a pipe burst, that is, a gas explosion.

When the liquid and gas coexist in the pipeline, the friction resistance and local resistance of the liquid flowing in the pipeline are increased.When it is heavy, it can even cut off the water flow, which greatly increases energy consumption and operating costs. The gas-collecting part of the pipeline accelerates the corrosion of the pipeline, reduces the strength of the pipeline, and When the liquid pressure of the pipeline fluctuates in a certain amplitude, the pipe explosion will occur.

Due to the existence of gas, the liquid flow of the pipeline is not stable, causing pipeline vibration, and the pipeline under the action of long-term vibration, resulting in loose leakage at the connection and even pipeline fracture, also causing a waste of resources and energy.

In the water supply pipeline system, in order to prevent water hammer from causing damage to the pipeline, water towers or pressure stabilization systems will be set up, these methods can only reduce the energy of water hammer, but can not solve the gas hazard in the pipeline. Therefore, it is necessary to install and use exhaust valves in the pipeline reasonably.

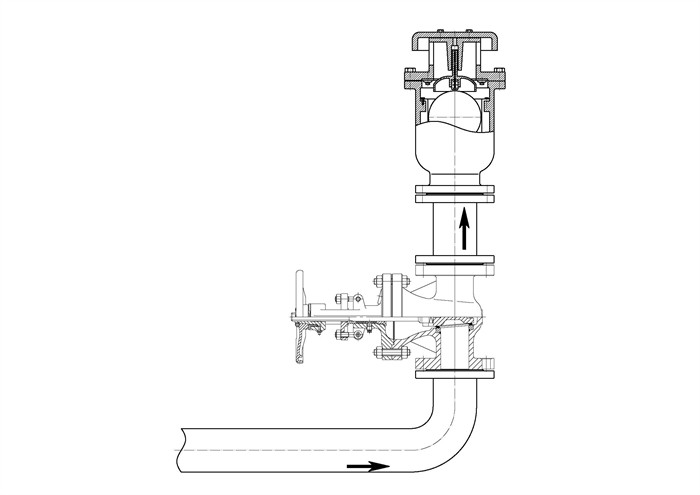

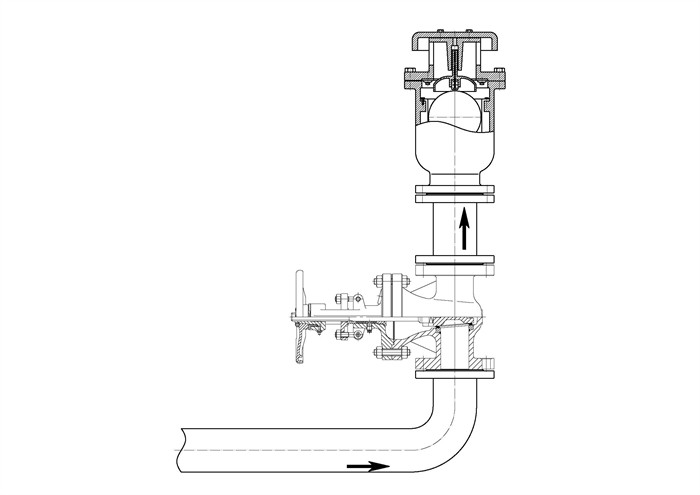

3. The new floating ball composite exhaust valve

The new floating ball composite release valve changes the internal structure of the valve body according to the principle of aerodynamics, so that the high-speed flow of gas in the valve body generated in the low pressure area to move down to the lower end of the valve disc, even if the gas flow rate reaches the speed of sound, the resultant force of the valve disc is still downward, only when the liquid level rises, the float ball and the valve disc are pushed up by buoyancy, the main valve is closed. When the gas gathered in the pipeline enters the exhaust valve, the float ball drops to open the micro-exhaust valve and remove the gas. The valve is sensitive to ensure the normal and safe operation of the pipeline.